What are the different types of Anti Vibration Mounts?

There are lots of different types of anti vibration mounts that support and stabilise pipework and plant room machinery. This includes open/closed spring mounts, heavy duty restrained springs and rubber turret supports. The product that you need depends on a variety of factors, such as reason for support, weight load, size and more.

Spring mounts are a type of anti vibration mount. They consist a framed spring that lifts and supports mechanical equipment to reduce noise and vibrations that may otherwise cause significant damage to pipework, and surrounding building structures. The spring allows for a gap where the equipment can move freely without damage or disruption. This means that they have a great shock absorption rate that will contribute towards increasing the lifespan of machinery. Anti vibration mounts are easy to install and are available in a variety of sizes, load capabilities and designs.

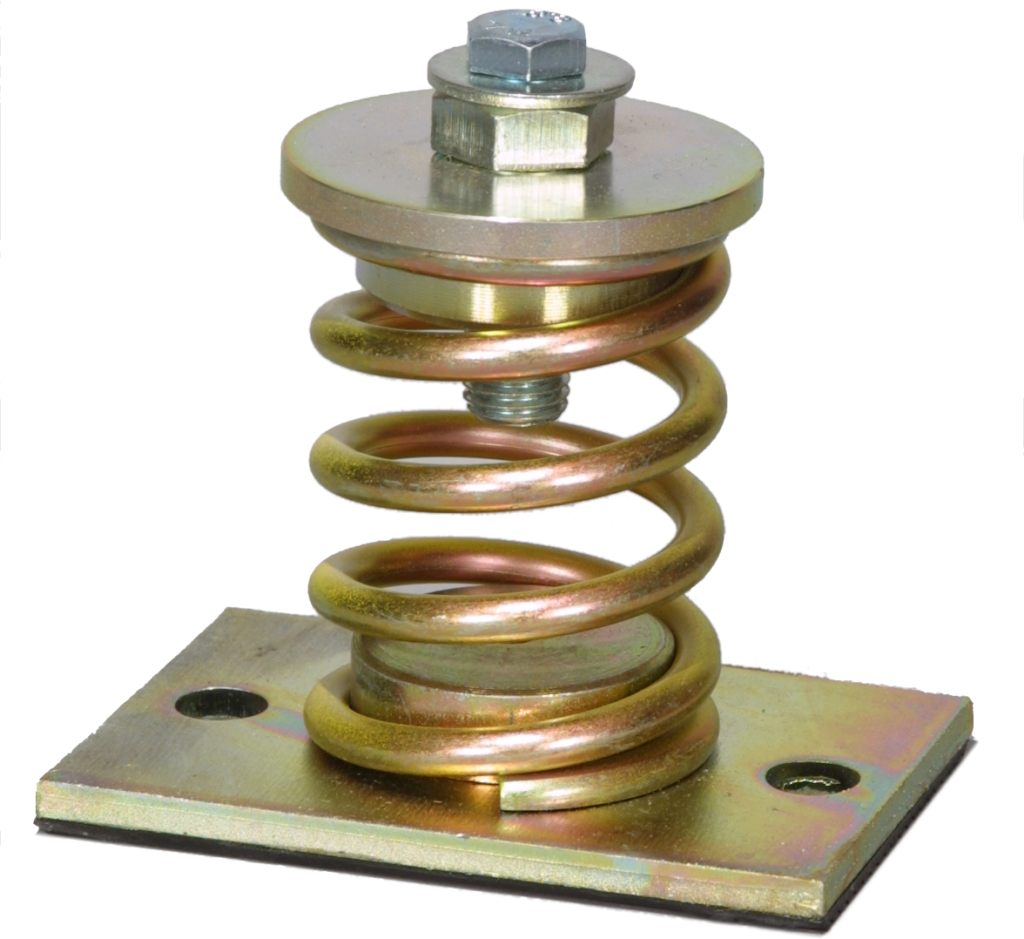

For example, our EMFLEX Spring Mounts are manufactured to cater for all kinds of pumps, but they are typically used for low frequency vibration damping such as coolers or chillers. They can be used in a system with multiple open springs to increase stability in systems, especially for heavier equipment loads. To learn more about how we can help, simply send us your equipment schedule, and our experts will provide you with the most thorough and cost-effective solution to minimise noise and disruption.

Typical anti vibration mounts are used in conjunction with our EMFLEX Inertia Bases to provide thorough support to plant room equipment. This is especially the case where heavy duty machinery is used, such as pumps, chillers or generators. A choice of our spring mounts or rubber turret mounts are used in this instance. The spring works to minimise and stabilise excessive movements, while our rubber mounts significantly reduces noise. Click on our product data sheets to learn more about our individual products.

How does vibration isolation work?

Anti vibration mounts work by compressing proportionally to the load applied, allowing for heavy duty machinery to be supported. When our spring mounts are used with our rubber bellows, this creates a reliable vibration minimiser that protects pipework systems and building structures.

Our EMFLEX Open Spring Mounts work to isolate mechanical equipment which produce lower frequency vibrations. They are placed below mechanical equipment and offer a more cost-effective solution to solving vibration problems that occur with rotating plant equipment.

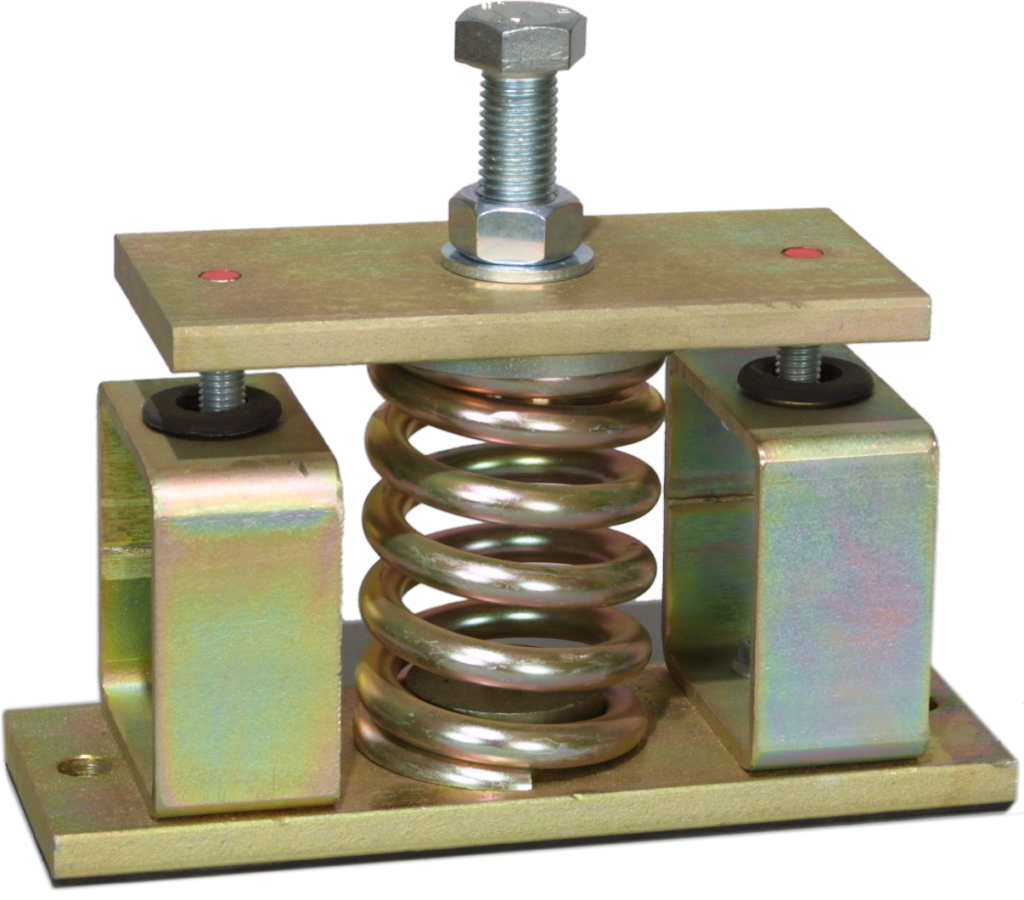

Our EMFLEX Heavy Duty Restrained Spring Mounts are used beneath mechanical equipment, either alone or with inertia bases, to minimise noise transmission and unwanted vibrations from machinery.

How the team at Minikins can help you

If you’re looking for free expert help on how to minimise noise and disruption from plant room machinery, then get in touch with one of our team members today.

With every enquiry, our experts will provide free marked-up designs, product information, installation information, guidance on care and maintenance and more. We also offer on-site visits to ensure that our products have been installed correctly. Simply get in touch with one of our team members today to learn more.