Product Code: BLF/N

Product Code: BATN

Product Code: BAF/N (X) (E)

Product Code: BHF/N

Product Code: BDHF/N

Product Code: BAC

What are pipe expansion joints?

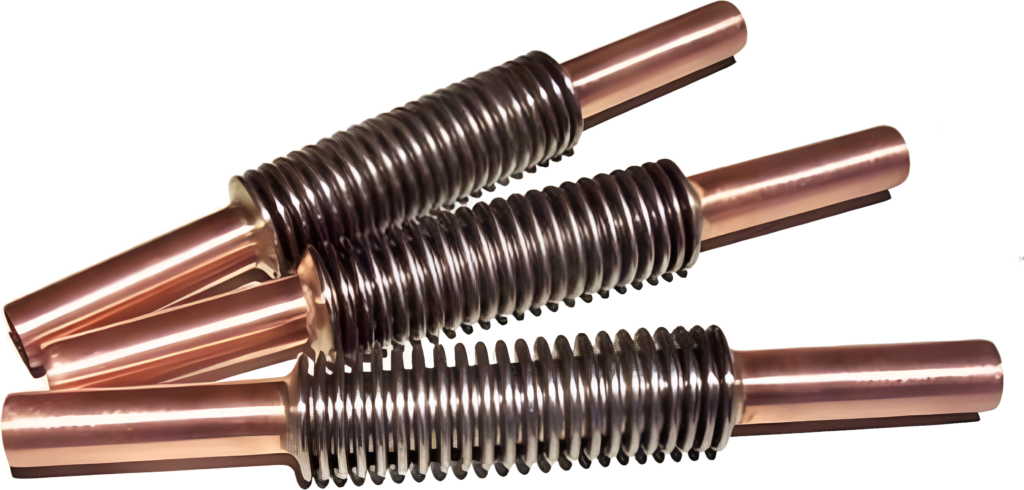

Pipe expansion joints are distinctly manufactured devices that absorb thermal expansion forces to protect pipework systems. They contain metal convolutions that expand or contract along with the pipework to absorb any thermal movement as a result of temperature changes. Axial expansion bellows are used to absorb thermal expansion in a straight length of pipework between two anchors, whereas lateral expansion bellows absorb movement assisted by a bend at the end of the pipework run.

Where are pipe expansion joints required?

The precise locations for expansion below are calculated by our experts based on a variety of factors. When a pipeline is subjected to a change in temperature, it will either expand or contract in direct proportion to that change. To calculate the amount of expansion, we will examine:

- Temperature changes (usually from 0°C).

- Length of pipework involved.

- Coefficient of thermal expansion of the material.

- The route which your pipework takes (natural flexibility).

Our experts are here to do all of your calculations on your behalf to ensure the durability of your pipework. We will also provide details of our recommended products tailored to your designs, along with precise guidance on installation locations.

As a general rule, pipe expansion joints will be required on pipelines that are longer than 20 metres. Calculations to decide on the correct distance between expansion bellows will also be conducted by one of our experts. This is measured on temperature, expansion rates and pipe materials. The higher the temperature the larger the expansion, but the rate of expansion depends on the pipe materials used. Multi-Layered Composite Pipe (MLCP) has a high coefficient of thermal expansion, followed by copper and stainless steel pipeworks, while carbon steel has the lowest temperature.

The type of joint required also depends on the direction of the movement when thermal expansion occurs. For example, we supply our Screwed Axial Expansion Joints for straight pipelines, while our Lateral Expansion Joints cater for expansion using bends. For more advice and guidance on our products, get in touch with one of our experts using the consultation form at the bottom of this page.

Guarantee your pipe service life with our high quality products

With over 40 years experience of catering for your thermal expansion and pipework needs, our experts at N. Minikins & Sons are here to provide solutions for any of your complex design or engineering requirements. Get in contact with one of our helpful team members to learn more.

All our EMFLEX expansion bellows are manufactured in accordance with the Expansion Joint Manufacturers Association (EJMA) calculations, meaning that they’re designed for safe and reliable piping.

Not only this, but to ensure engineering excellence our products also conform to The Pressure Equipment Directive (PED) 97/23/EC when required. Please note that it is the responsibility of our customers to ensure that all products are installed correctly to comply with PED 97/23/EC.

Our products and services are all in accordance with the Quality Management System under ISO 9001.